Bulk Material Transport fast like the Wind.

Pneumatics is often the perfect solution for the conveyance of dry bulk materials: overpressure and underpressure create a fast air flow inside the pipelines, which transports the material directly to the desired location. Safe, simple and cost-efficient. This makes pneumatic conveying the optimal bulk material transport.

Structure and Function

The pneumatic conveying systems always consist of a dosing- and a blower unit and the air and conveying pipeline.

Telschig mainly use the positive pressure conveying method as thin-flow or dilute-flow conveying. The dosing method used to feed the bulk material into the air stream of the pipeline depends, among other things, on the physical product properties, the conveying capacity and the discharge source (i.e. bag emptying machine, silo, …). Three dosing devices can be considered for this purpose: the screw pump called screw material feeder SMA (similar to the Fuller Pump), rotary valves or Venturi Eductors.

The dosing device is used for optimal dosing of the material into the air stream in order to achieve a perfect mixing ratio between air and bulk material.

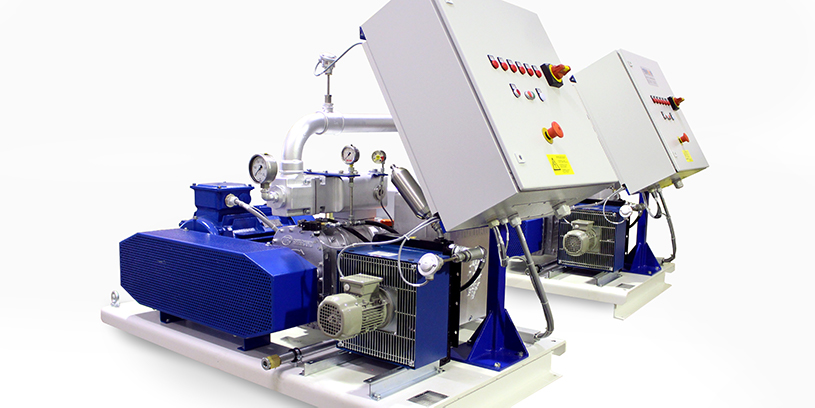

The air volume with the necessary pressure is provided by the blower unit. The blower is designed individually and exactly to the (customer’s) requirements. This depends, among other things, on the conveying distance, conveying capacity and the product characteristics of the bulk material.

The selection of the suitable dosing device and the exact design of the blower unit as well as the correct pipeline routing are essential for the design of the pneumatic conveying system.

Best Product Features

- Conveying capacity up to 75 t/h

- Conveying distances up to 150 meters

- Conveying pressures up to 2.5 bar

- overpressure Customized engineering

- Robust technology for trouble-free continuous operation

- Compact construction/design

- Dust-free mode of operation

Cemtrans

The special form of our pneumatic conveying systems. Optimized for the transfer of bulk materials such as cement, fly ash, microsilica and others. For example, from the storage silo to the work silo. Or from the rail car to the storage silos.

The machine consists of an individual receiving container, the SMA conveyor unit and its own compact conveying air supply. Only the provision of electrical power is required from the operator.

With an intuitive interface, the system control is designed for easy operation, even with gloves on.

Conveying capacities of up to 60 m³/hour over distances of 30- 100 meters are standard applications..

Cembulk

The compressor for receiving/ terminals. Designed for unloading silo vehicles without on-board compressor, the Cembulk is also suitable for unloading ships and railroad waggons.

Cemobil

Cemobil is a mobile, manual bag emptying machine. The entire system is located on a mobile mounting frame, which can also be stationary if required. With well thought-out features, Cemobil makes cement processing easier and more efficient at your construction site.

References

Are you interested in our Pneumatic Conveying Systems? Please have a closer look at some of our references.

Contact

Find out more about our extensive range of services! Get an instant call back from our sales engineers.